In the constantly evolving manufacturing industry, robots play a essential to bringing innovation and efficiency. Industrial robotics has revolutionized manufacturing, bringing businesses many benefits that include increased productivity, quality and competitiveness. Manufacturing robots play an essential part in the future of manufacturing as the demands for automation continue to increase.

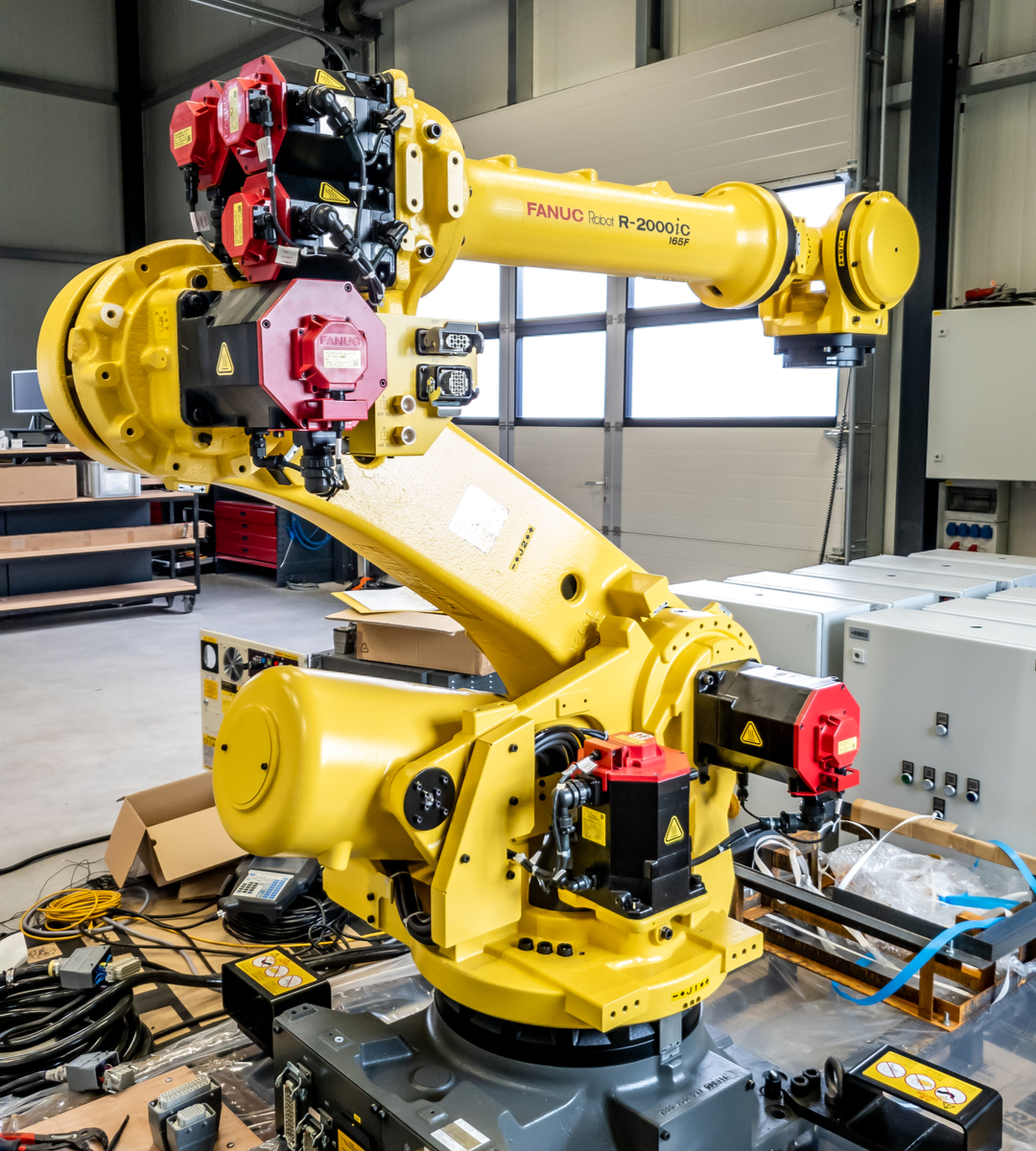

Manufacturing robots, often referred to as industrial robots, are machines designed to perform various tasks within the manufacturing process. They are used for welding paint, assembly, along with picking, placing and packing. The field of industrial robotics is the study and use of robots. It focuses on increasing productivity and precision during manufacturing processes.

One of the companies at the forefront of this revolution is Automated Solutions Australia (ASA) which is a specialist in creating industrial robots to offer the most flexible automation solutions to manufacturing customers. ASA’s industrial robots help clients gain an edge in the market through boosting productivity and quality. ASA industrial robotic solutions are highly sought-after by businesses across many industries like pharmaceuticals, electronics and automotive.

The benefits of implementing industrial robots in manufacturing are multifaceted. The most significant benefit is improvement in productivity and efficiency. Industrial robots can handle repetitive tasks with accuracy and a consistent manner. This results in increased production rates and shorter durations of cycle. This improves overall productivity but also allows businesses to meet ever-growing consumer requirements with ease.

Additionally, industrial robots help improve the quality control of manufacturing processes. These robots decrease the probability of errors by executing tasks efficiently and accurately which results in better quality products. As a result, you will have a higher degree of satisfaction with the customer and a better image for the business.

Alongside efficiency and quality, industrial robotics also offer cost-saving benefits. The initial costs of producing robots could be high however the benefits over time are significant. Businesses can lower operational costs by streamlining processes and reducing manual labor. Additionally, industrial robots work around the clock to maximize the utilization of resources while reduce production costs.

Another benefit of industrial robots can be their impact on workplace surroundings. They’ve been engineered to create low noise levels. This creates a more comfortable and quieter working environment. Additionally, their precision and speed create creating a safer work environment by reducing the risk of accidents and injuries associated with manual labor.

The integration of industrial robots also plays a crucial role in the creation of jobs and the future of work. Though there are concerns about whether robots could replace humans, industrial robots can actually provide new employment opportunities. They offer roles related to robot programming and maintenance, as well as supervision and supervision, as well as the development of innovative technologies to support robotic manufacturing.

In the various industries, businesses continue to profit from the advantages of industrial robots as manufacturing continues to adopt this technology, it’s changing the business. Industrial robotics have the potential to increase efficiency, cost effectiveness and quality. It is changing the manufacturing industry, and set new standards of excellence.

In conclusion, robotics in manufacturing are a paradigm shift in manufacturing. The integration of these technological advances can help businesses reach new levels of performance, precision, competitiveness, and efficiency. Industrial robots will play an important role as the demand for automation grows. They are able to determine the future of manufacturing and propel the pace of innovation.