Wire rope lubricators and wire cleaners and other sophisticated tools are vital in the complicated world of cable maintenance. Efficiency and longevity are vital. These devices are innovative and serve as a key element in ensuring the smooth functioning and longer life of cables in a variety of industries. In this post, we dive into the role of lubricating and lubricating wire ropes as well as wire cleaners in maintenance of cables, exploring their functions as well as the benefits and profound impact they play on the overall efficiency of operations.

Understanding wire rope lubricators

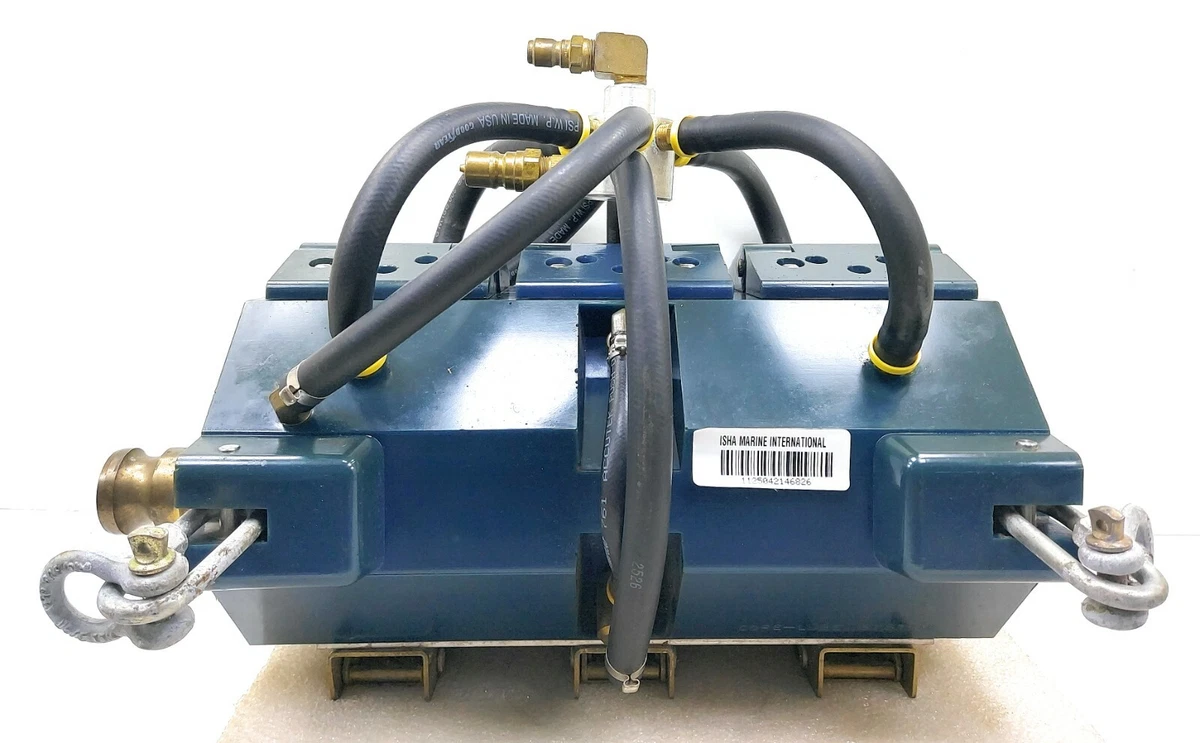

Wire rope lubricators, also called wire rope lubricators, are specialized devices that apply grease to the ropes in a systematic manner. This is essential to the prevention of corrosion, decreasing friction, and enhancing the overall longevity of the cable. The lubricator is responsible for ensuring that the lubricating agents are evenly distributed throughout the length of the wire ropes, safeguarding them from wear and tear.

The role of wire cleaners in Cable Maintenance:

Wire cleaners (also called cable cleansers) are also essential to maintaining the hygiene and cleanliness of cables. These cleaners are created to eliminate fluids, contaminants and dirt that build up on cables during various activities. In environments with harsh conditions using wire cleaning products is vital to ensure optimal performance.

Optimizing Cable Lifespan:

Combining wire cleaners with greasers for wire rope can help extend the lifespan of cable. By systematically applying lubrication with wire rope lubricators and removing dirt with wire cleaners the cables are protected from the damaging consequences of corrosion, friction and other external elements. The integrity of the cable is protected and this results in greater operational efficiency and lower maintenance costs.

Effectiveness in Application

Wire rope lubricators have been designed to make use of easy and effectiveness when used. These lubricators are flexible and can be used with various wire rope types and sizes. Automated and systematic lubrication eliminates the risk of uneven applications that manual techniques can cause.

Ability to adapt to challenging environments

The adaptability of the cleaning and lubrication of wire ropes is essential in any industry that exposes cables to harsh environments. This is the case for drilling, construction and maritime activities. These devices are engineered to stand up to harsh environments and are therefore reliable tools for maintenance of cables in different situations.

Cost-Effective Maintenance Solutions:

Adopting a proactive method of maintenance of your cables by making application of lubricators for wire ropes and wire cleaning products proves to be a cost-effective option over the long term. These sophisticated tools can be a minimal investment when as compared to the expense of repair, replacement and downtime which could result from neglecting maintenance. Know more at Wire Cleaner

Conclusion:

Lubricators and wire cleaners for wire ropes are the guardians who ensure cable integrity and accuracy across a broad range of industries. Cleansing away contaminants and the use of lubricants aids in the long-term preservation and durability of cables. This helps reduce maintenance and improves operational efficiency. Cables are still in use in the most critical sectors, therefore the use of tools to maintain cables that help maintain their reliability and performance is vital.