As the global plastic pollution crisis grows more severe, new recycling techniques are emerging as critical tools to create a sustainable future. Systems that can reduce plastic waste into reusable materials and then integrate it into the manufacturing process are among the most significant advances. The techniques, which range from shredding through granulating and pelleting, are transforming the way industries manage waste. In the forefront of this transformation is Jian Kwang Machine Industrial, which has state-of-the-art equipment that allows companies across the world to minimize environmental impact while maximizing material recovery and efficiency.

Plastic Shredder Machines – The Foundation

The journey from plastic waste to reusable material begins by using a plastic shredder. These sturdy machines were created to handle the task of breaking down a variety of plastics waste, ranging from consumer packaging to scraps of industrial waste into smaller, more manageable pieces. Recycling shredders, for example, uses advanced blade configurations, high torque motors, as well as other features to shred even tough materials like PET bottles or PVC pipe.

Image credit: jkm3r.com

The first step in processing the plastic waste is shredding it. By shredding the volume and size of plastic waste, shredders increase efficiency and decrease wear and wear on equipment downstream. Jian Kwang’s shredders are constructed using precision engineering and have earned trust from customers in areas like the Middle East, Africa, and Europe. They are indispensable for large-scale recycling facilities that aim to meet strict environmental standards due to their ability to handle operations with high volumes of throughput.

Granulation – Refining plastic for reuse

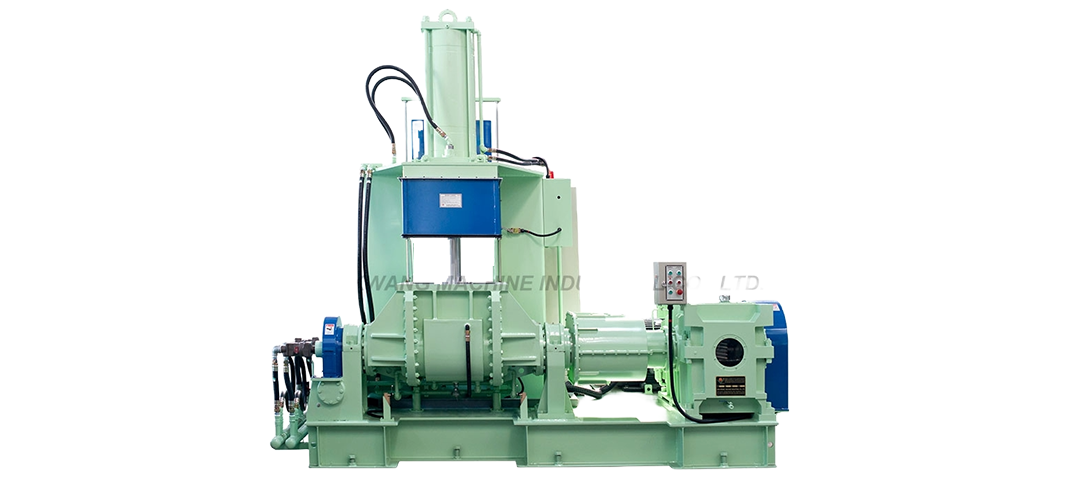

The plastic fragments that have been shredded require additional refinement before they are able to be utilized for manufacturing. Plastic recycling granulator machine take these fragments and convert them into uniform granules that are easier to melt, mold, and transform into new products. Jian Kwang’s innovative systems include high-speed mixers as well as dispersion kneaders. This guarantees that every batch of granules meet strict standards in terms of quality, density, and size, making them ideal for producing consistent high-quality products.

Granulation is a crucial step to ensure the quality of the material. In addition, residual contaminants or inconsistent particle sizes could affect the efficiency of recycled plastic. Jian Kwang’s complete plant system, that combines crushers, granulators and extruders, offers a seamless workflow to optimize output. International manufacturers have embraced these processes, such as Crocs, Inc. that relies on recycled granules that provide durability and sustainability.

Pelletizing is the building blocks of recycling

The process of plastic pelletizing is among the most advanced in recycling. It converts waste that is granulated into uniform pellets that are utilized to create new products. Pelletizers melt the granules, push them through a machine, and finally make them into pellets using advanced technology like water-ring technology or strand cutting. Jian Kwang’s pelletizing machine is known for its accuracy. It produces pellets that are consistent in dimensions and shapes. This is critical for applications such as automotive packaging and consumer products.

The circular economy is founded on the idea of pelletization. It is more than just a method. These machines reduce the need for virgin plastics by creating high-quality, durable pellets. This reduces costs and environmental impacts. Jian Kwang designs that are ingenious, such as their water-ringcutting kneader-extruding plants enhance pellet quality while minimizing the waste. This efficiency has made Jian Kwang’s machines a popular choice for clients throughout South America and the USA, where sustainability regulations are increasingly demanding.

Vision for a Sustainable Future

Jian Kwang Machine Industrial is distinguished not only by its technological capabilities, but also its commitment to sustainability as well as customer success. The red sun of Taiwan and Ali Mountain’s ‘green’ are a reflection of the values of consistency, trust, and collaboration. This is the guiding principle behind their R&D to ensure that every plastic shredder as well as recycling shredder has unbeatable performance.

Beyond the manufacturing process, Jian Kwang provides comprehensive support, from timely maintenance to custom turnkey solutions such as two-color stationary use plate plants. Jian Kwang’s global reach and capacity to meet a wide range of client requirements is evident in their support to clients including small recyclers such Crocs to giants in the industry like Crocs. By fostering environmentally sustainable manufacturing Jian Kwang empowers businesses to align with environmental goals and maintain profitability.

A Circular Economy for the Building

Recycling machines for plastic like the plastic shredder, plastic granulator and plastic pelletizing machines go far beyond being industrial tools. These machines can be used to create the creation of a more sustainable environment. In converting waste plastic into valuable pellets, these machines reduce landfill reliance, conserve resources, and encourage sustainable production. Jian Kwang’s expertise will help the recycling industry to face the challenges of the future while building a sustainable and more promising future.