Computer Numerical Control machining (CNC) has changed the way manufacturing and engineering is conducted in the last couple of decades. CNC machining, which blends the latest technology in manufacturing with traditional processes, has become the predominant method for manufacturing high-precision components and products to suit a broad range of industries. This article will explore the mechanics, benefits and varied applications of CNC machining to highlight the impact it has on engineering technology of the present.

The mechanisms of CNC Machining

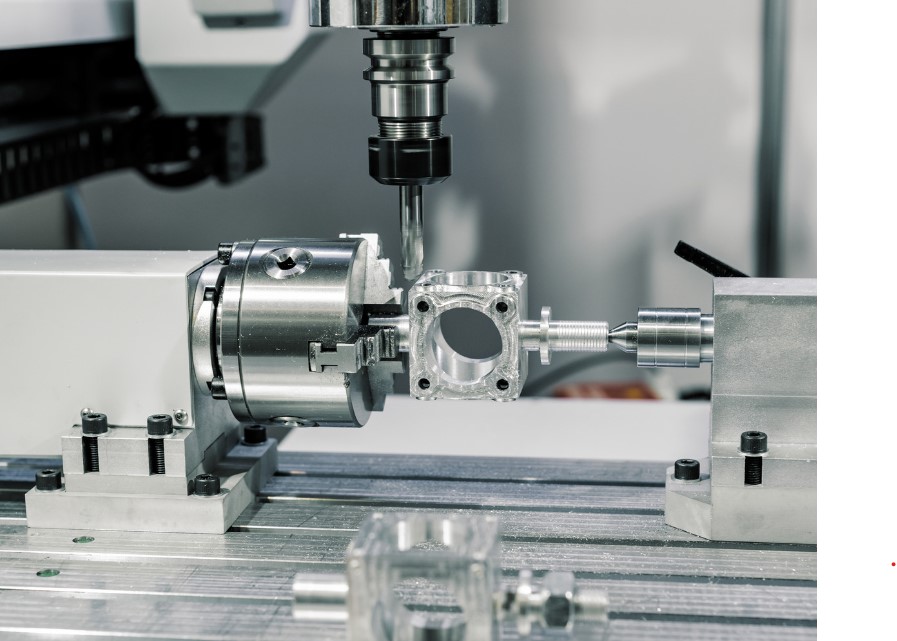

CNC machining is a subtractive manufacturing technique that is, it takes the material from a solid block or workpiece in order to achieve the desired shape. This process is governed by an application that has been programmed to control the motion of the machine. The code produced by CNC machines is dependent on the type of machine being used as well as the complexity of the item. But, the idea remains the same. A high-speed cutter precisely cuts away material to form the final product.

The precision of CNC machined parts is among the most important advantages. Digitalization permits extremely precise and consistent production. This minimizes human error, and ensures an even distribution of batches. This level is critical for industries such as medical devices, aerospace, and manufacturing of automobiles, where small deviations can lead to serious consequences.

The role of digital computer systems for CNC machine operation

The integration of digital technology is at the heart of CNC machining’s efficiency and accuracy. CNC machines are controlled by specialized software that automates the entire manufacturing process. This software converts computer-aided design (CAD) designs into a sequence of precise directions, which the CNC machine then is able to follow to produce the piece. The instructions set everything from speed and direction to depth and angle for every cut.

In industrial plants with large capacity computers are often integrated directly into CNC machines. This permits seamless communication and controls. This integration allows for real-time monitoring that ensures high performance and minimizes downtime. The automation of CNC machineries also permits continuous operation, thereby significantly increasing efficiency and reducing the time it takes to complete.

CNC Machining: Its Advantages

CNC machining is a superior method for manufacturing. Its capability to make intricate and complex components that are precise is one of the biggest advantages. The precision of CNC machineries eliminates the need to make manual adjustments or the need for rework, decreasing waste and improving efficiency. CNC machines can also be used continuously and are ideal for large production runs.

CNC milling has another benefit it’s flexibility. With the option of changing the programming it is possible to make a variety of different parts. CNC machines are adaptable and is suitable for prototyping as well in mass production. This allows manufacturers to rapidly respond to market demands changes.

The process of automating CNC machines also increases safety at work. Injuries and accidents are less likely when manual intervention is not necessary. In addition, the high-quality of CNC-machined parts enhances product reliability and performance, which contributes to the satisfaction of the customer and enhancing the reputation of the brand.

Industries benefiting from CNC Machining Services

The precision, versatility and effectiveness of CNC machining are utilized in a variety of industries. In the aerospace industry, CNC machines produce critical components that must meet stringent safety and performance standards. CNC machines are employed in the medical device industry to produce complex implants and surgical instruments where accuracy is key.

CNC machining can be used to produce engine parts and transmissions, as well as intricate interior and exterior elements, and even more complex exterior and interior designs for the automotive industry. Similar to this, the electronics sector benefits from CNC’s ability of producing small, detailed components that are used in consumer electronics, communication devices, and other electronic items. The art and jewelry industries make use of CNC technology to produce intricate designs and custom pieces.

The Future of CNC Machining

CNC machining is expected to expand as technology continues to improve. CNC’s capabilities will further be enhanced by technological advancements like multi-axis machine as well as additive manufacturing and advanced materials. Furthermore, machine learning and AI will enhance CNC machine efficiency.

CNC machining, with its unmatched effectiveness, precision and efficiency is having a huge impact on modern manufacturing and engineering. Its ability to make intricate parts with high accuracy is a crucial tool in a variety of industries. CNC manufacturing, as the technology advances is expected to remain an integral component in manufacturing’s future.